« Factory/en » : différence entre les versions

Page créée avec « {| class="wikitable" |- style="vertical-align:top;" | 600px | The "Products Used" tab of the product sheet summarizes the products used for each of its tasks. |- style="vertical-align:top;" | 600px | {{Note|Clicking on the + displays the task on which the product is used.}} To make a stock movement, click on the missing quantity of product. |- style="vertical-align:top;" | fil... » |

Page créée avec « ===Loss Management=== {| class="wikitable" |- style="vertical-align:top;" | 700px | Component losses are recorded in the manufacturing report. Lost components will be deducted from inventory. Others can be returned to inventory. |- style="vertical-align:top;" | 700px | In the following case, the plan was to manufacture four composite products. We will record the manufacture of three products and the loss of on... » |

||

| Ligne 389 : | Ligne 389 : | ||

This feature allows you to perform composition tests for a product or keep updated compositions on the product according to seasonality. | This feature allows you to perform composition tests for a product or keep updated compositions on the product according to seasonality. | ||

When a project is validated, it is possible to enter the product consumption for the task with the '''Adjust quantities''' button. | |||

<div lang="fr" dir="ltr" class="mw-content-ltr"> | <div lang="fr" dir="ltr" class="mw-content-ltr"> | ||

Version du 7 mai 2025 à 17:09

|

CAPM Tool - Composition, Direct Manufacturing, Manufacturing Orders, and Variations |

Overview

Features

Factory is Dolibarr's CAPM tool that allows you to:

|

|

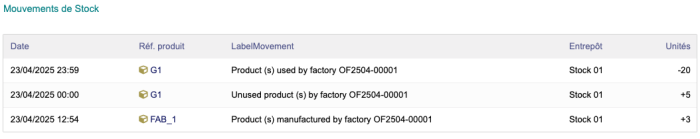

Factory creates the stock movements for different products:

A dedicated tab allows for display: |

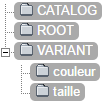

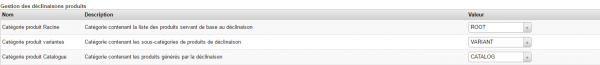

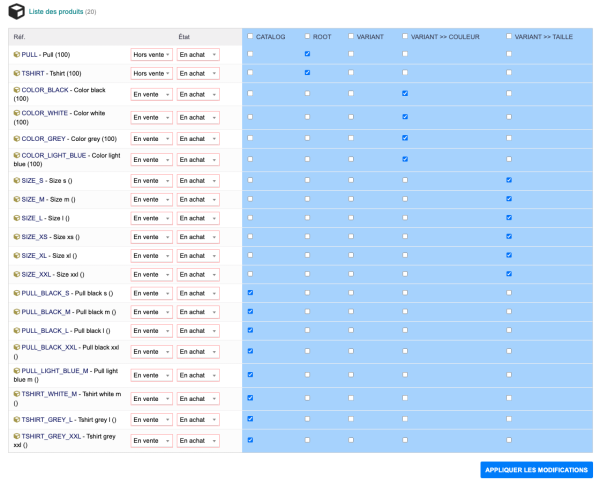

Factory also provides the functionality of creating product variations: from the product categories defined in the module configuration, Factory creates product variations according to their variants.

Combined with the Project module, Factory allows the recording of compositions on tasks and allows the monitoring of consumption and their transfer to other tasks.

NEW: The Factory module allows you to view the component tree (and their subcomponents) and all the components that make up the component. It is possible to associate a Production Order with a project (and track associated production orders from within a project).

Factory Free and Factory Premium

Factory was distributed in a free & limited version and a premium version.

Since the arrival of a native GPAO function (MRP) in Dolibarr, the free version is no longer maintained

Settings

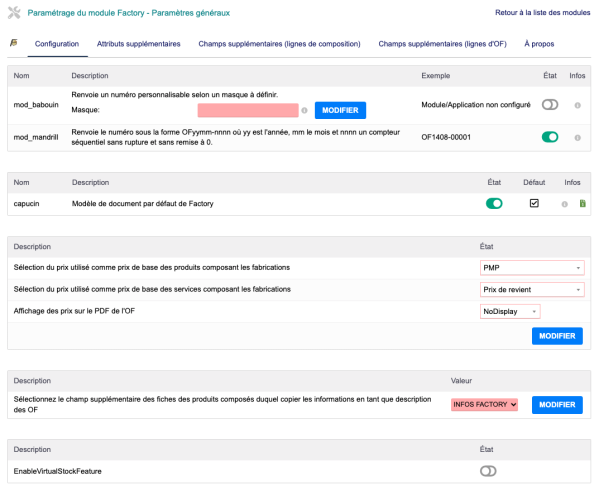

Configuration

Module Feature Configuration

|

Module configuration is performed from the module administration page, accessible via the "Home > Configuration > Modules" menu by clicking on the |

The Factory module allows you to customize the numbering mask for production orders.

| Factory requires the activation of the numbering and document templates |

Use of the product declination feature requires declaration on this page of the product categories used.

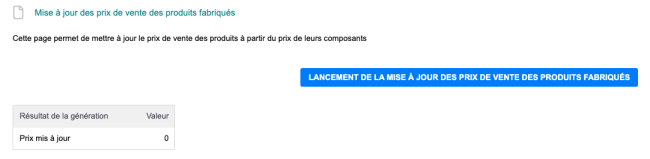

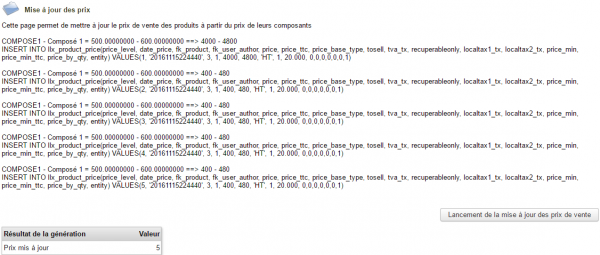

Factory has a price update tool that can be activated on this same page.

Factory per and to choose the value to use for the price of the components depending on whether they are products or services.

Finally, by enabling the "Select the additional field from which to copy information as a work order description" feature, it is possible to copy the contents of an additional field present on the composite product sheets as a work order description. Select the additional field containing the data here.

Creating Additional Fields

The module supports the creation of additional fields. These fields will allow you to display custom fields on the module's element sheets, where you can record any additional information you may need.

Creating additional module-specific fields follows the same procedure as creating additional fields on native Dolibarr elements. You can create additional fields for:

- Composition lines

- Production orders

- Production order detail lines

| If the additional fields for the composition lines and the production order detail have the same name (and the same type), their values are passed on when the production order is created. |

Dictionary

The module relies on Dolibarr dictionaries to assign contacts/addresses to a production order.

Factory offers four types of contacts/addresses by default: Production manager and contributor, internal and external for each.

You can create your own entries from Home > Settings > Dictionaries > Contact/Address Types

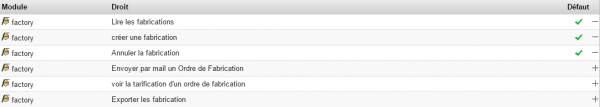

Permissions

Access to module features can be restricted to existing users and groups or those created after the module's installation. Click the – button to add a permission. A granted permission is indicated by a green check mark (![]() ).

).

User and Group Permissions

|

Access to module features can be restricted to users and groups, from their profile and then the Permissions tab, according to the permissions opposite. |

Default Permissions

|

The default permissions (Home > Settings > Security > Default Permissions), granted to any user created after the module is installed, if they are not added to a group, are as follows: |

Getting Started

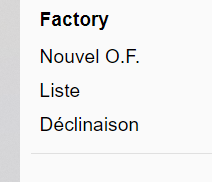

Factory features are accessible from the main menu tab "Products/Services" or the "MRP/CAPM" menu (depending on the Dolibarr version and the enabled modules). class="wikitable

! colspan=2| Your secondary menu then displays the following menu items:

|-

|rowspan="6" style="vertical-align:top;" |

| style="vertical-align:top;" |

Factory: Displays the factory "space" with dashboards showing module usage.

|-

| New Work Order: Allows you to directly create a Production Order (PO) by selecting either a product with a defined composition or a BOM.

|-

| List: This entry will display the list of production orders entered in your database. The list offers numerous sorting and filtering options.

|-

| Consumption Report: This menu allows you to view monthly and annual consumption. You can view the times the planned and actual consumption.

|-

| Time Report: The module allows you to enter times associated with employees for services used in a work order. It is possible to plan times, as well as those actually used. This entry is made on a work order tab that will be presented in the documentation (Associated functionality / provided by the TimeKeeper module).

|-

| Declination: The Declination entry will display the page for launching the generation of declinations. The operation of this page requires the correct configuration of all necessary elements.

|}

| style="vertical-align:top;" |

Factory: Displays the factory "space" with dashboards showing module usage.

|-

| New Work Order: Allows you to directly create a Production Order (PO) by selecting either a product with a defined composition or a BOM.

|-

| List: This entry will display the list of production orders entered in your database. The list offers numerous sorting and filtering options.

|-

| Consumption Report: This menu allows you to view monthly and annual consumption. You can view the times the planned and actual consumption.

|-

| Time Report: The module allows you to enter times associated with employees for services used in a work order. It is possible to plan times, as well as those actually used. This entry is made on a work order tab that will be presented in the documentation (Associated functionality / provided by the TimeKeeper module).

|-

| Declination: The Declination entry will display the page for launching the generation of declinations. The operation of this page requires the correct configuration of all necessary elements.

|}

Definition of a Product's Composition

Prerequisites

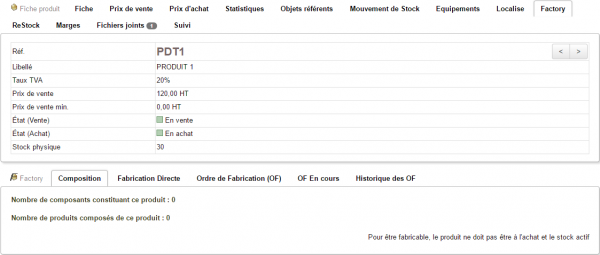

For a composite product to have a composition, it must be of a "manufactured" nature.

The composition is carried out by the selection of predefined products and/or services.

|

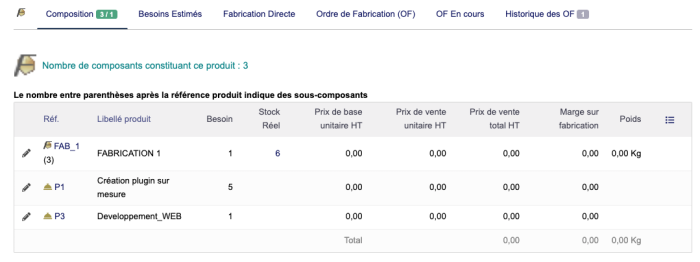

The manufacturing features, whether direct or by production order, are accessible from the "Factory" tab of the product page and then from the second-level tabs. |

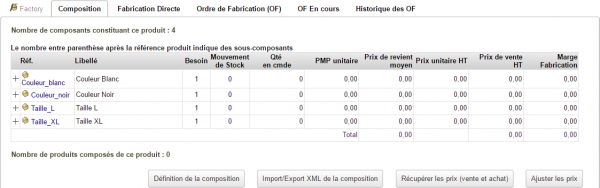

Composition Determination

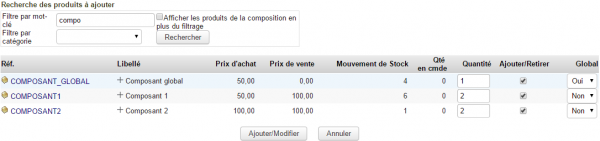

Click the "Composition" tab and then the "Composition Definition" button to select the component products.

|

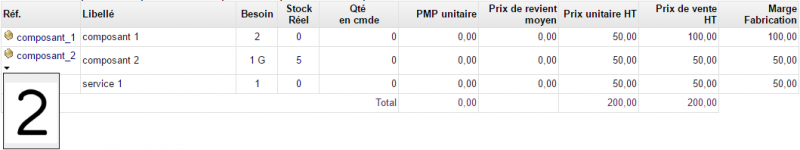

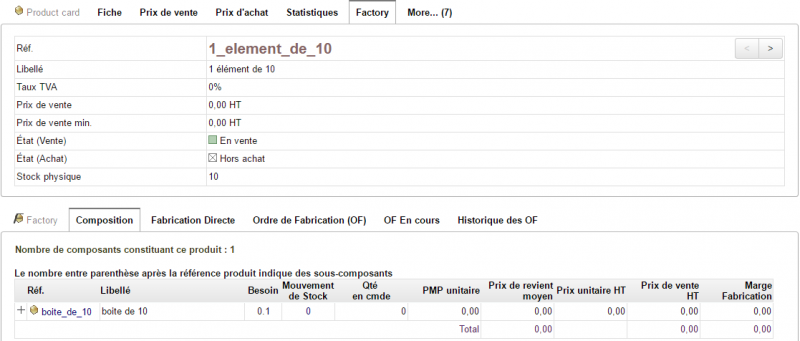

Specify the quantities of each component for the production of one unit of the composite product. You can specify whether the quantity will be consumed globally (see note below). Check the box and click the "Add/edit" button to confirm your entry. |} Product Variant CompositionWhen using product variants, it is possible to retrieve the parent product's composition directly from the variant sheet. Composition and DecompositionFactory also allows you to decompose products by entering a quantity in decimal format as follows: Let's take a box of 10 items to be decomposed into 10 individual items. |

Please note that the operating mode has changed; you must now enter a negative value to break down a product.

Manufacturing LevelsFactory can manage multiple manufacturing levels, including component products themselves produced through manufacturing.

Deleting ComponentsTo delete a component from a composition, return to the product composition, click the Composition Definition button, uncheck the boxes of the components to be deleted, and then save your changes.

Composition Options

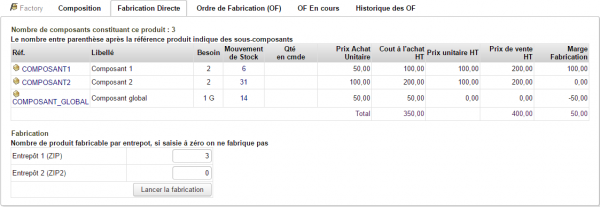

Direct Manufacturing

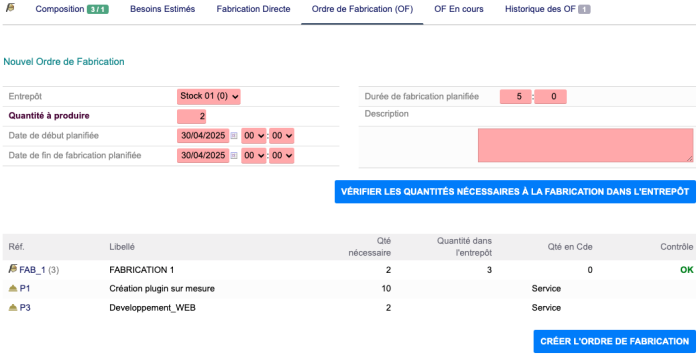

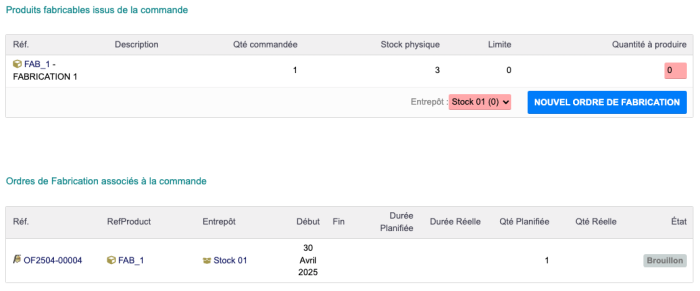

Production Orders (PO)Production orders allow you to plan your production. You can create a production order from product sheets or from customer order sheets. Creating and Launching from Product Sheets

Finally, click the "Create Manufacturing Order" button. The page will then display the list of production orders for the product to be manufactured.

Creating and Launching from Customer Order Records

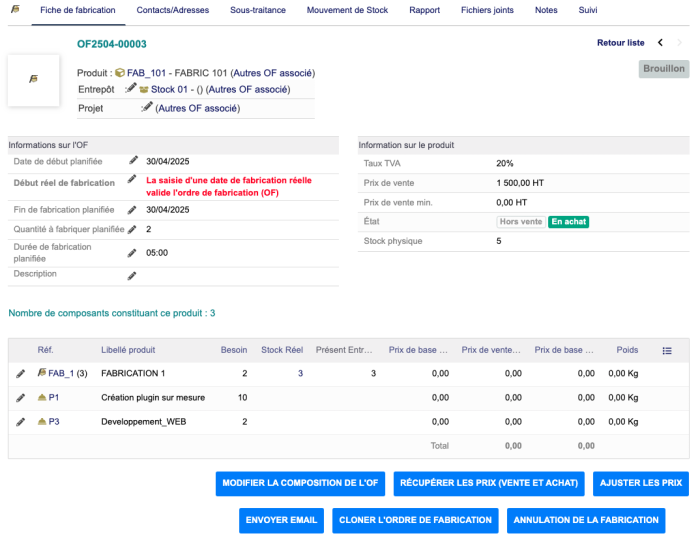

Working Order Form ButtonsAt this stage, you can:

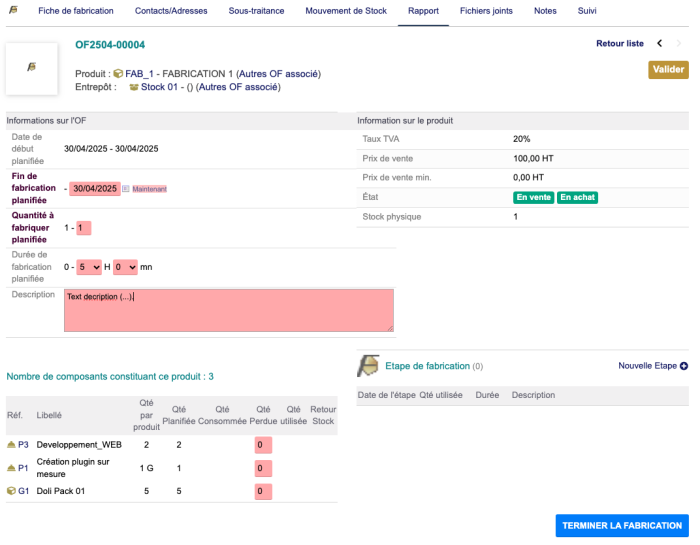

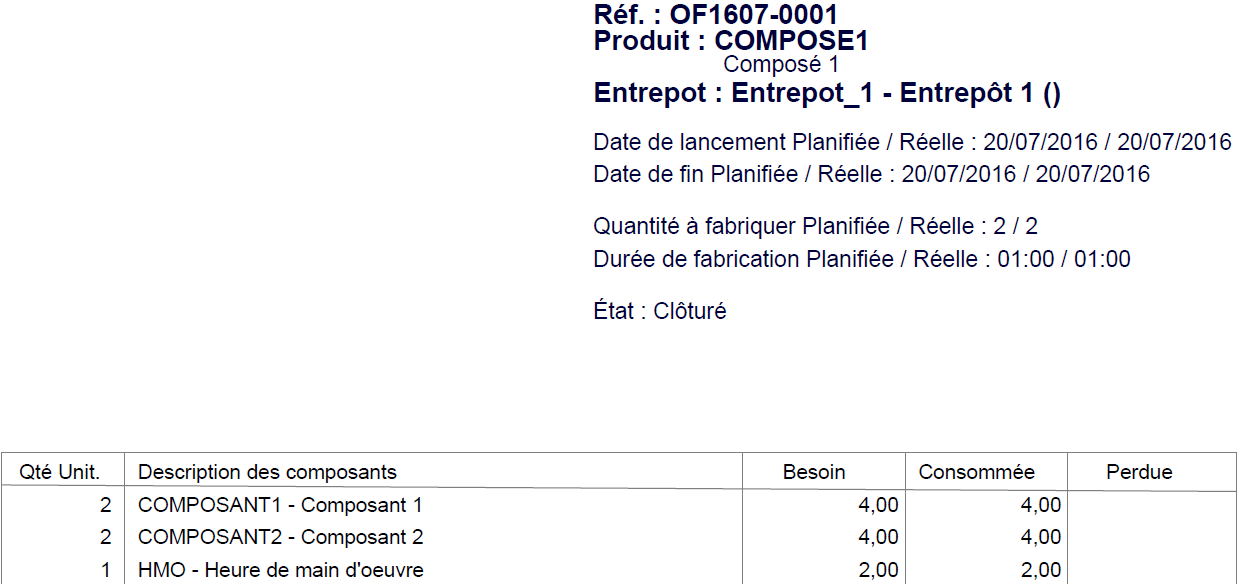

Validating and Reporting a Production OrderTo validate the production order, enter its actual production date by clicking the

Editing the PDF of Production Orders

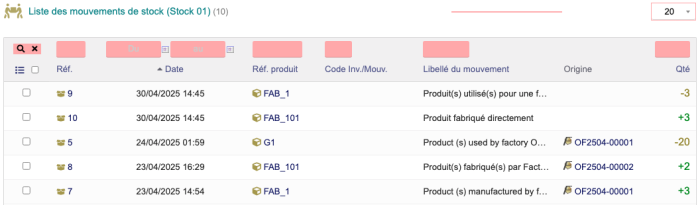

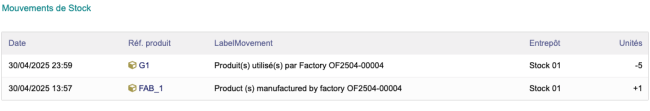

Stock Movements

Loss Management

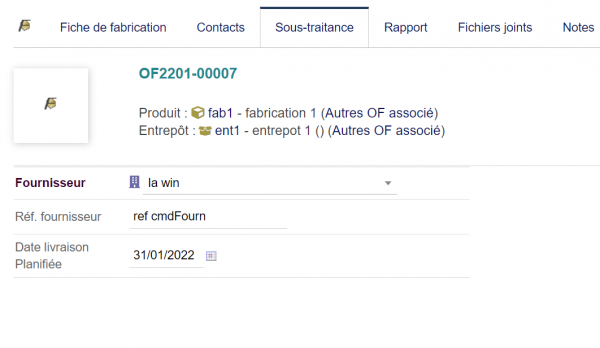

Consumption ReportFactory allows you to track monthly and annual product consumption. Subcontracting ManagementOperating PrincipleIt is possible to subcontract a production order to a subcontractor and track it from the work order.

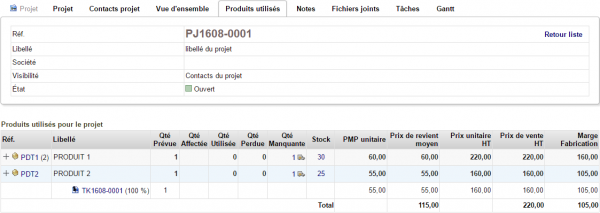

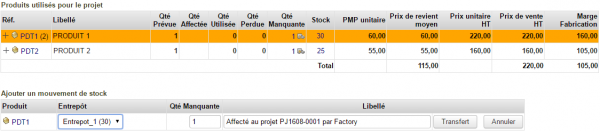

Factory and ProjectsOperating PrincipleFactory allows you to manage the creation of unique parts or the consumption of products for projects. This management is done by associating products with project tasks. When the project is active/valid, it is possible to enter the products consumed on the tasks.

A custom product is a set of products and services associated with each other. Unlike a mass-produced product, a custom product is not manufactured according to a predefined composition and is not referenced in the Dolibarr product list. The selection of products associated with a stain follows the same procedure as that for defining the composition.

Finally, the single product / project mode also offers the possibility of associating the products selected in a task with a product using the use the composition in a product button. When the project is closed, it is possible to use the composition transfer function on an existing product. Task compositions of a closed project can be transferred to another task with the Transfer to another task button. This feature allows you to perform composition tests for a product or keep updated compositions on the product according to seasonality. When a project is validated, it is possible to enter the product consumption for the task with the Adjust quantities button. Ces quantités sont de deux types :

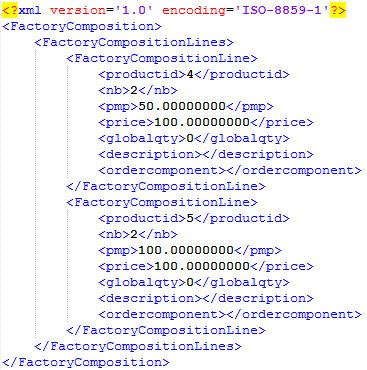

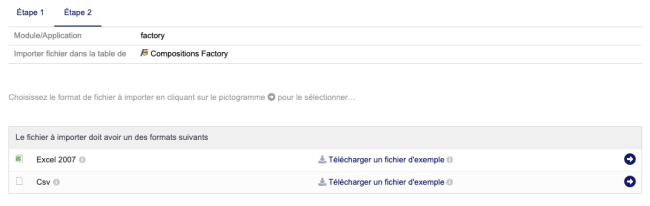

Le calcul de la quantité manquante s’effectue de la manière suivante : Si Qté Prévue > (Qté Utilisée + Qté perdue) Alors Qté Manquante = Qté Prévue – Qté Affectée Sinon Qté Manquante = (Qté Utilisée + Qté perdue) – Qté Affectée Autres fonctionnalités de FactoryImport de compositions

Export de compositions

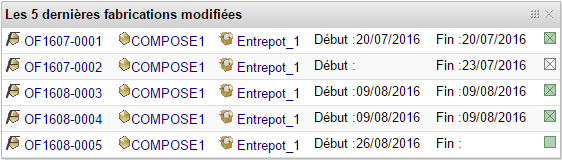

Afficher/masquer les données tarifaires des produits composantsLa permission utilisateur voir la tarification d'un ordre de fabrication permet de cacher à certains utilisateurs les informations tarifaires Widgets en page d'accueil

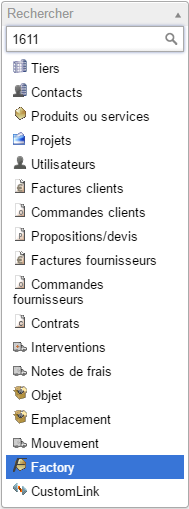

Recherche d'ordre de fabrication

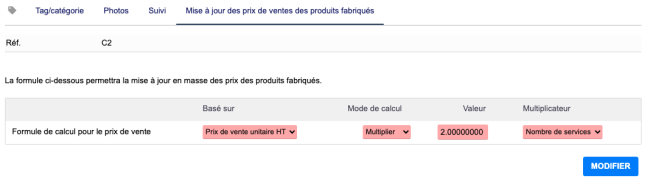

Fonctionnalités annexes à FactoryChangement en masse des prix des produits fabriquésFactory permet d'enregistrer des formules de calcul qui s’appliqueront au prix des produits composés selon les prix des produits composants. Cette fonctionnalité nécessite l’utilisation des catégories dans lesquelles les produits composés doivent être classés afin de pouvoir être pris en compte par les formules.

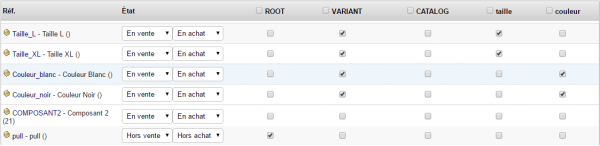

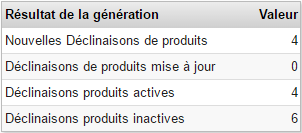

DéclinaisonsLe but de la fonction est de générer autant de produits qu’il y a de déclinaisons définies. Pour cela, Factory utilise à la fois la création de composition et la gestion des catégories de produits/services. Les produits doivent être classés dans 3 catégories distinctes :

Depuis le lien de menu secondaire Produits/services > Factory > déclinaisons, cliquez sur le bouton Lancer la génération des déclinaisons produits.

Questions fréquentesGénéralesCe chapitre répertorie les difficultés rencontrées avec le module. Vous y trouverez donc des éléments de réponse quant à son utilisation. Si vous rencontrez une autre erreur que celles décrites ci-dessous lors de l'utilisation de ce module :

Si, malgré ces manipulations, l'erreur persiste, contactez-nous en utilisant le formulaire dédié (http://docs.patas-monkey.com/support/). Ce formulaire est le mode de contact à privilégier pour toute difficulté d'utilisation ou remontée de bug. Aussi, nous vous remercions de ne pas multiplier les canaux d'échange pour un même objet. Message d'erreur suite à l'installation

Défaut d'incrémentation des références des OF

|

|---|