« Factory/en » : différence entre les versions

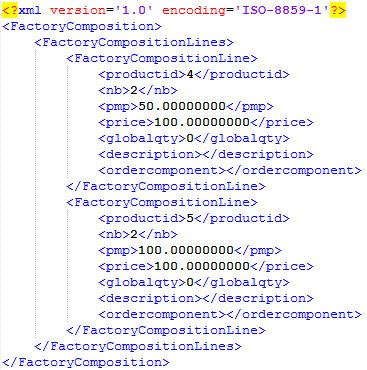

Page créée avec « |Select the manufacturing warehouse and the quantity of products to be manufactured, the planned manufacturing start and end dates and, if necessary, a manufacturing duration and description. » |

Aucun résumé des modifications |

||

| (59 versions intermédiaires par 2 utilisateurs non affichées) | |||

| Ligne 12 : | Ligne 12 : | ||

{| class="wikitable" | {| class="wikitable" | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

[[file:factory-Composition- | [[file:factory-Composition-crea_en.png|600px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

*Define the composition of a composite product based on predefined products and services. | *Define the composition of a composite product based on predefined products and services. | ||

| Ligne 21 : | Ligne 21 : | ||

{| class="wikitable" | {| class="wikitable" | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

[[file:factory-OF-mouvement- | [[file:factory-OF-mouvement-stock_en.png|600px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

Factory creates the stock movements for different products: | Factory creates the stock movements for different products: | ||

| Ligne 48 : | Ligne 48 : | ||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory- | | [[file:factory-Configuration_en.png|599px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

Module configuration is performed from the module administration page, accessible via the "Home > Configuration > Modules" menu by clicking on the [[file:doli-setup.png]] or [[file:doli-setup-old.png]] icon at the bottom of the line. | Module configuration is performed from the module administration page, accessible via the "Home > Configuration > Modules" menu by clicking on the [[file:doli-setup.png]] or [[file:doli-setup-old.png]] icon at the bottom of the line. | ||

| Ligne 65 : | Ligne 65 : | ||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory-Information- | | [[file:factory-Information-dolibarr_en.png|600px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

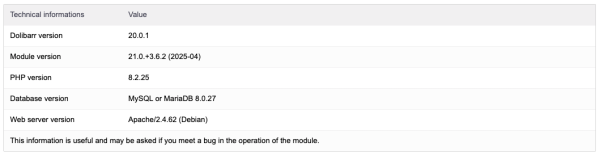

At the bottom of the configuration page, you will find technical information related to your installation. This technical information will be useful and may be requested if you encounter a bug while using the module. | At the bottom of the configuration page, you will find technical information related to your installation. This technical information will be useful and may be requested if you encounter a bug while using the module. | ||

| Ligne 89 : | Ligne 89 : | ||

{| class="wikitable" | {| class="wikitable" | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

[[file:factory- | [[file:factory-Dictionnaire_en.png|599px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

Select "Factory" from the drop-down list, the contact type (internal for a user, external for a third-party contact), a code, and a label that will be displayed in the selection list of the contacts/addresses tab of a Factory. | Select "Factory" from the drop-down list, the contact type (internal for a user, external for a third-party contact), a code, and a label that will be displayed in the selection list of the contacts/addresses tab of a Factory. | ||

| Ligne 101 : | Ligne 101 : | ||

====User and Group Permissions==== | ====User and Group Permissions==== | ||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory-Permissions- | | [[file:factory-Permissions-utilisateurs_en.png|600px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

Access to module features can be restricted to users and groups, from their profile and then the Permissions tab, according to the permissions opposite. | Access to module features can be restricted to users and groups, from their profile and then the Permissions tab, according to the permissions opposite. | ||

| Ligne 108 : | Ligne 108 : | ||

====Default Permissions==== | ====Default Permissions==== | ||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory-Permissions- | | [[file:factory-Permissions-defaut_en.png|600px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

The default permissions ('''Home > Settings > Security > Default Permissions'''), granted to any user created after the module is installed, if they are not added to a group, are as follows: | The default permissions ('''Home > Settings > Security > Default Permissions'''), granted to any user created after the module is installed, if they are not added to a group, are as follows: | ||

|} | |} | ||

==Getting Started== | ==Getting Started== | ||

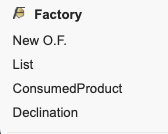

Factory features are accessible from the main menu tab "Products/Services" or the "MRP/CAPM" menu (depending on the Dolibarr version and the enabled modules). class="wikitable | Factory features are accessible from the main menu tab "Products/Services" or the "MRP/CAPM" menu (depending on the Dolibarr version and the enabled modules). | ||

{|class="wikitable | |||

! colspan=2| Your secondary menu then displays the following menu items: | ! colspan=2| Your secondary menu then displays the following menu items: | ||

|- | |- | ||

|rowspan="6" style="vertical-align:top;" | | |rowspan="6" style="vertical-align:top;" | | ||

[[file:factory- | [[file:factory-Menusecondaire_en.png]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

'''Factory''': Displays the factory "space" with dashboards showing module usage. | '''Factory''': Displays the factory "space" with dashboards showing module usage. | ||

| Ligne 133 : | Ligne 133 : | ||

| '''Declination''': The Declination entry will display the page for launching the generation of declinations. The operation of this page requires the correct configuration of all necessary elements. | | '''Declination''': The Declination entry will display the page for launching the generation of declinations. The operation of this page requires the correct configuration of all necessary elements. | ||

|} | |} | ||

==Definition of a Product's Composition== | ==Definition of a Product's Composition== | ||

| Ligne 142 : | Ligne 141 : | ||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory-Onglet- | | [[file:factory-Onglet-factory_en.png|600px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

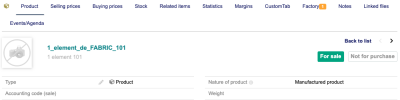

The manufacturing features, whether direct or by production order, are accessible from the "Factory" tab of the product page and then from the second-level tabs. | The manufacturing features, whether direct or by production order, are accessible from the "Factory" tab of the product page and then from the second-level tabs. | ||

| Ligne 153 : | Ligne 152 : | ||

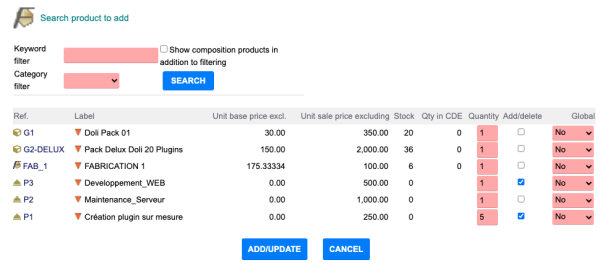

| {{Note|For quick searches, you can filter the list of products to select from the composition}} | | {{Note|For quick searches, you can filter the list of products to select from the composition}} | ||

{{Note|When a composition is saved for a product, the "Show composition products in addition to filtering" checkbox allows you to display the component products already saved in addition to the filter results}} | {{Note|When a composition is saved for a product, the "Show composition products in addition to filtering" checkbox allows you to display the component products already saved in addition to the filter results}} | ||

[[file:factory-Composition- | [[file:factory-Composition-crea_en.png|600px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

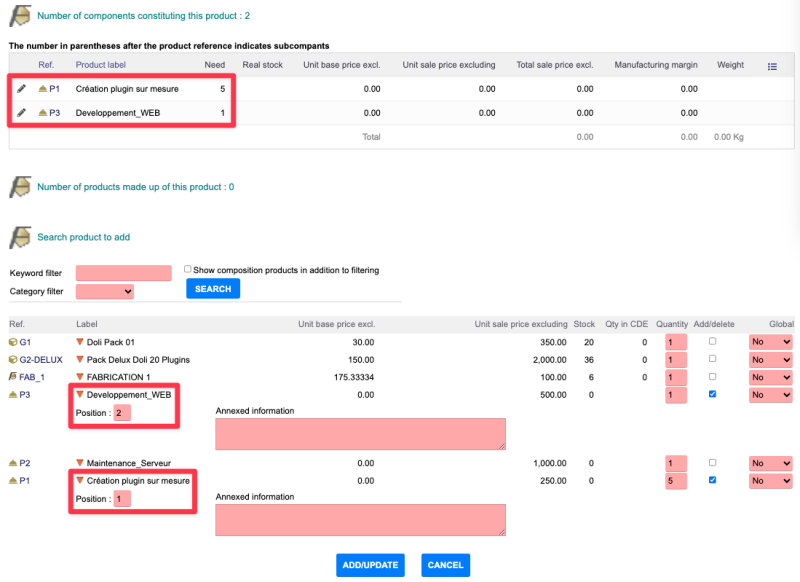

Specify the quantities of each component for the production of one unit of the composite product. | Specify the quantities of each component for the production of one unit of the composite product. | ||

You can specify whether the quantity will be consumed globally (see note below). | You can specify whether the quantity will be consumed globally (see note below). | ||

Check the box and click the "Add/edit" button to confirm your entry. |} | Check the box and click the "Add/edit" button to confirm your entry. | ||

|} | |||

{{Note|The quantity used of a product defined as global to a composition will remain unchanged regardless of the quantity of the composite product manufactured (ex: manufacturing one or five composite products requires a single unit of labor each time.)}} | {{Note|The quantity used of a product defined as global to a composition will remain unchanged regardless of the quantity of the composite product manufactured (ex: manufacturing one or five composite products requires a single unit of labor each time.)}} | ||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory-image- | | [[file:factory-image-produit_en.png|800px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

When selecting components for a composition, you can order them by entering a position and add a note. These two options are accessible by clicking the + in front of the component label: | When selecting components for a composition, you can order them by entering a position and add a note. These two options are accessible by clicking the + in front of the component label: | ||

| Ligne 180 : | Ligne 180 : | ||

| Two products will need to be created | | Two products will need to be created | ||

|- style="vertical-align:top;" | | |- style="vertical-align:top;" | | ||

| [[file:factory- | | [[file:factory-Factory10_en.png|400px]] [[file:factory-Factory1_10_en.png|400px]] | ||

|- style="vertical-align:top;" | | |- style="vertical-align:top;" | | ||

| and the element composition saved as shown opposite | | and the element composition saved as shown opposite | ||

|- | |- | ||

| [[file:factory- | | [[file:factory-Decompostion2_en.png|800px]] | ||

|} | |} | ||

| Ligne 191 : | Ligne 191 : | ||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory- | | [[file:factory-Recursivite_en.png|700px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

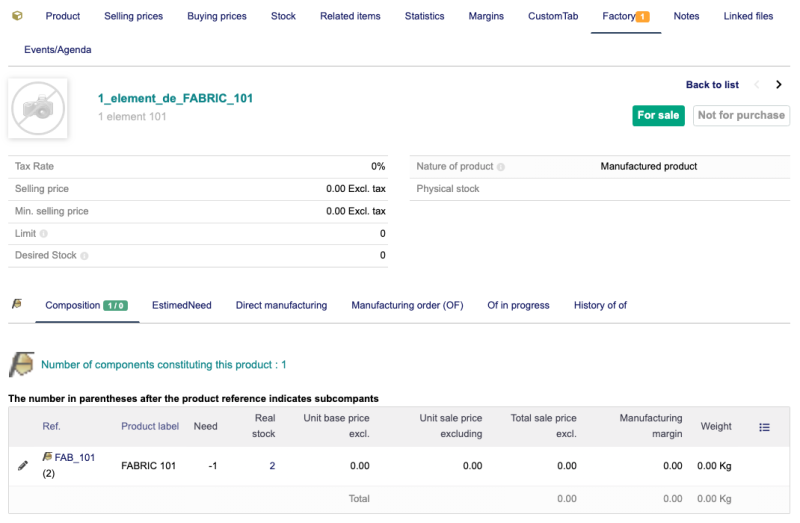

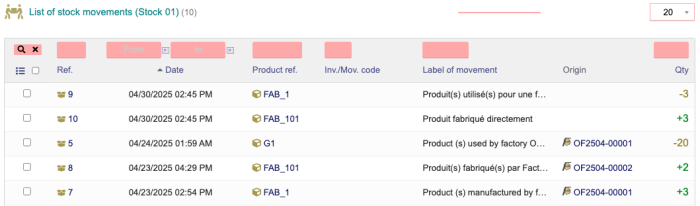

In a composition, if you select a product that is itself composed, the information will be given by the number in parentheses indicating the number of components in this product, which is '''(3)''' for FAB_1. | In a composition, if you select a product that is itself composed, the information will be given by the number in parentheses indicating the number of components in this product, which is '''(3)''' for FAB_1. | ||

| Ligne 216 : | Ligne 216 : | ||

{| class="wikitable" | {| class="wikitable" | ||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| [[file:factory-Fabrication- | | [[file:factory-Fabrication-directe_en.png|600px]] | ||

{{Note|If the component quantities are not in stock in the same warehouse, it will not be possible to start manufacturing.}} | {{Note|If the component quantities are not in stock in the same warehouse, it will not be possible to start manufacturing.}} | ||

| | | | ||

| Ligne 227 : | Ligne 227 : | ||

A confirmation message is displayed. The page then displays the updated quantities of products in stock. | A confirmation message is displayed. The page then displays the updated quantities of products in stock. | ||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| [[file:factory-Fabrication-directe-mouvement- | | [[file:factory-Fabrication-directe-mouvement-stock_en.png|700px]] | ||

| | | | ||

Warehouse stock movements display movements related to manufacturing. | Warehouse stock movements display movements related to manufacturing. | ||

| Ligne 238 : | Ligne 238 : | ||

{| class="wikitable" | {| class="wikitable" | ||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| [[file:factory-OF- | | [[file:factory-OF-creation_en.png|700px]] | ||

| | | | ||

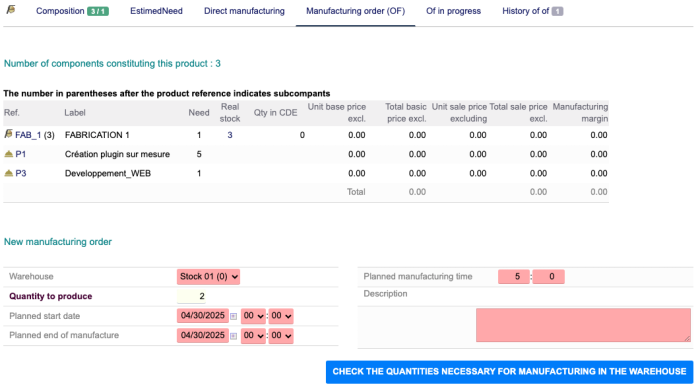

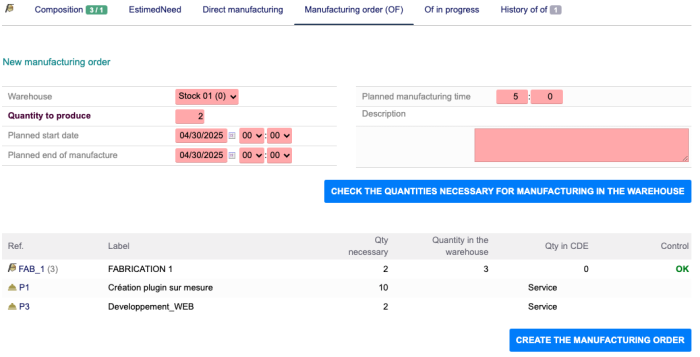

Once a product's composition has been saved, click on the second-level Manufacturing Order tab in the Factory tab of the product sheet to be manufactured. | Once a product's composition has been saved, click on the second-level Manufacturing Order tab in the Factory tab of the product sheet to be manufactured. | ||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| [[file:factory-OF- | | [[file:factory-OF-controle_en.png|700px]] | ||

{{Note|It is possible to create a manufacturing order even if there is insufficient stock on the creation date: You can replenish your warehouses between the creation date of the manufacturing order and its validation.}} | {{Note|It is possible to create a manufacturing order even if there is insufficient stock on the creation date: You can replenish your warehouses between the creation date of the manufacturing order and its validation.}} | ||

| Ligne 256 : | Ligne 256 : | ||

{| class="wikitable" | {| class="wikitable" | ||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| [[file:factory-OF- | | [[file:factory-OF-fiche_en.png|700px]] | ||

| | | | ||

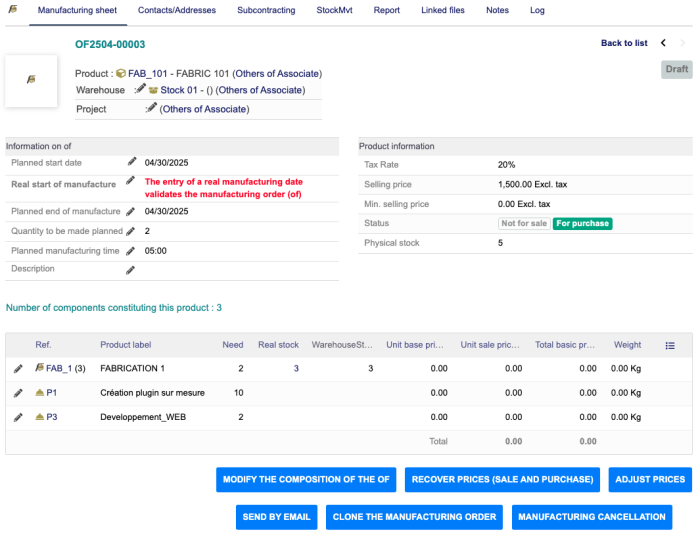

Open the production order file from the previous page or from the "Products/Services > Factory > List" menu link: | Open the production order file from the previous page or from the "Products/Services > Factory > List" menu link: | ||

| Ligne 265 : | Ligne 265 : | ||

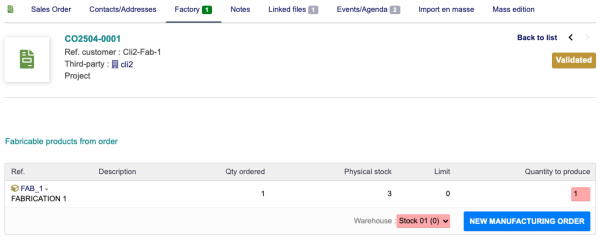

===Creating and Launching from Customer Order Records=== | ===Creating and Launching from Customer Order Records=== | ||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory-OF-depuis-commande- | | [[file:factory-OF-depuis-commande-client_en.png|600px]] | ||

{{Note|When creating a work order from a customer order, the suggested production quantity only takes into account the quantity of products present on the order.}} | {{Note|When creating a work order from a customer order, the suggested production quantity only takes into account the quantity of products present on the order.}} | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

Creating a work order from a customer order record follows the same creation procedure. The following steps are common, regardless of the source from which the work order was created. | Creating a work order from a customer order record follows the same creation procedure. The following steps are common, regardless of the source from which the work order was created. | ||

The page for creating a production order from a customer order is accessible from the Factory tab of its record. | |||

|} | |||

|} | |||

{| class="wikitable" | {| class="wikitable" | ||

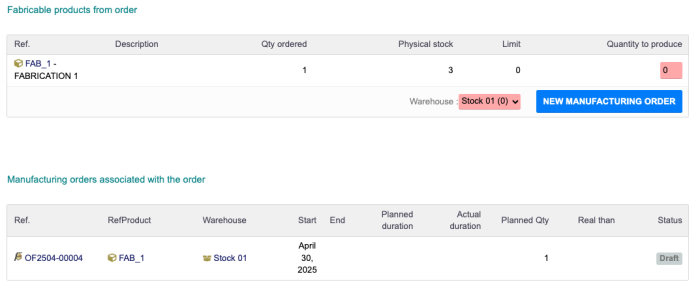

| [[file:factory-Lien-commande- | | [[file:factory-Lien-commande-of_en.png|700px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

{{Note| | {{Note|The production order linked to a customer order is indicated on the customer order record, Factory tab}} | ||

|} | |} | ||

===Working Order Form Buttons=== | |||

At this stage, you can: | |||

*Cancel the work order: Deleting a work order is not possible. You can only cancel it using the "Cancel Production" button. | |||

* | *Modify the work order composition: You can modify the product composition on the work order. Clicking this button will display the "Determine Composition" page. | ||

* | {{Note|Modifying the composition on the work order only applies to the work order and does not change the composition recorded on the Factory tab of the product sheet.}} | ||

{{Note| | *Sending the work order by email requires activating the email sending option and selecting a contact on the "Contact" tab of the work order (see Dictionary). *Clone the work order: cloning allows you to copy the work order by using or modifying the quantity, product and initial warehouse. | ||

* | |||

* | |||

===Validating and Reporting a Production Order=== | |||

To validate the production order, enter its actual production date by clicking the [[file:edit.png]] icon. | |||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory-OF- | | [[file:factory-OF-rapport_en.png|700px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

The production order will then change to the "Validated" status. All that's left to do is enter its report. | |||

Open the '''Report''' tab of the OF file. | |||

Confirm the '''quantity actually manufactured'''. Close the work order with the '''Complete production''' button. | |||

{{Note|Closing the work order is necessary to record stock movements from the work order|warn}} | |||

{{Note| | |||

|} | |} | ||

===Editing the PDF of Production Orders=== | |||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory-PDF- | | [[file:factory-PDF-of_en.png|700px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

{{Note| | {{Note|The PDF is enriched with information entered throughout the activity, particularly losses!}} | ||

|} | |} | ||

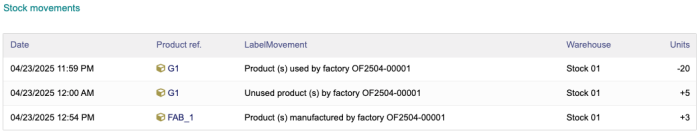

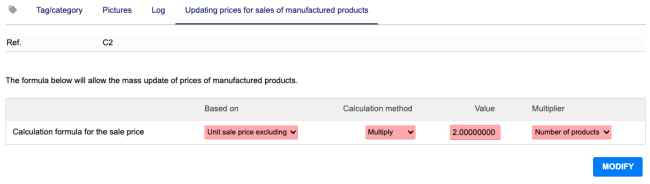

===Stock Movements=== | |||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory-OF-mouvement- | | [[file:factory-OF-mouvement-stock_en.png|700px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

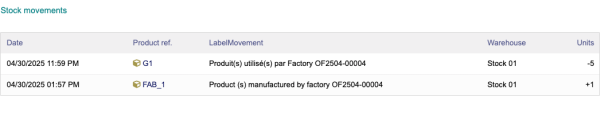

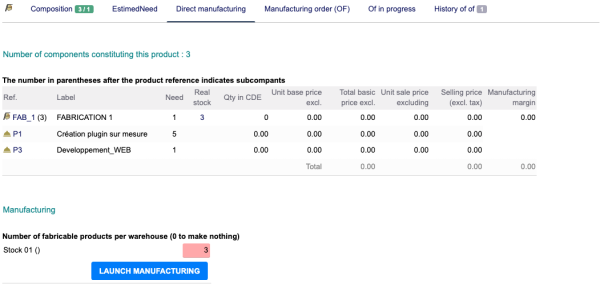

Once manufacturing is complete, stock movements are recorded. In the previous case, they are as follows: | |||

|} | |} | ||

{{Note| | {{Note|Stock movements related to the production order are accessible from the Stock Movements tab of its file and from the complete list of movements for a warehouse or product. They mention the origin (direct manufacturing or production order followed by its reference).}} | ||

===Loss Management=== | |||

{| class="wikitable" | {| class="wikitable" | ||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Perte1_en.png|700px]] | ||

| | | | ||

Component losses are recorded in the manufacturing report. Lost components will be deducted from inventory. Others can be returned to inventory. | |||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Perte2_en.png|700px]] | ||

| | | | ||

In the following case, the plan was to manufacture four composite products. We will record the manufacture of three products and the loss of one component, '''P3'''. | |||

Factory automatically calculates the quantities of products lost or returned to stock based on the quantities actually manufactured and the products declared lost. | |||

Factory | |||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Perte2stock_en.png|700px]] | ||

| | | | ||

Stock movements related to the work order will then be: | |||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

|} | |} | ||

{{Note| | {{Note|In the case of products and not services (products return to stock and services will not be counted).}} | ||

== Consumption Report == | |||

Factory allows you to track monthly and annual product consumption. | |||

Factory | |||

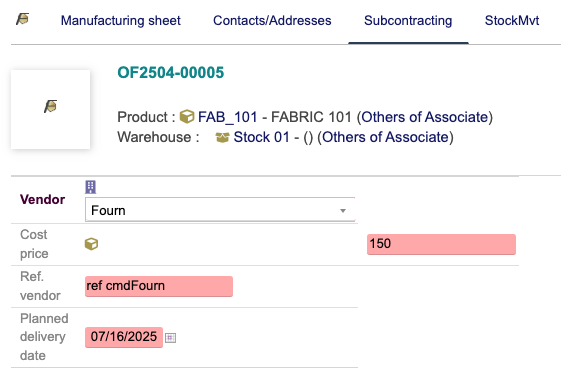

== Subcontracting Management == | |||

=== Operating Principle === | |||

=== | It is possible to subcontract a production order to a subcontractor and track it from the work order. | ||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory- | | [[file:factory-soustraitance1_en.png|600px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

Start by selecting the subcontractor from the dedicated tab at the work order level. | |||

and creating an associated supplier order. | |||

|} | |} | ||

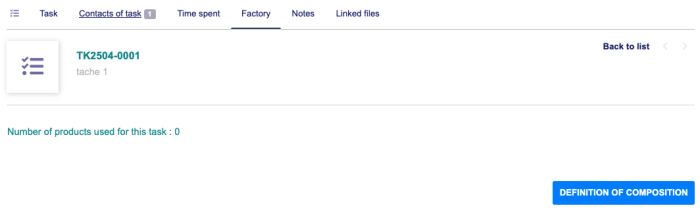

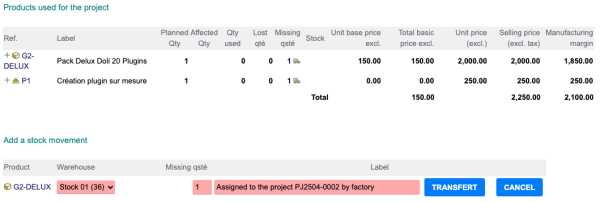

==Factory and Projects== | |||

==Factory | ===Operating Principle=== | ||

=== | Factory allows you to manage the creation of unique parts or the consumption of products for projects. This management is done by associating products with project tasks. | ||

Factory | |||

When the project is active/valid, it is possible to enter the products consumed on the tasks. | |||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory-Onglet-factory- | | [[file:factory-Onglet-factory-tache_en.png|700px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

Factory | Factory adds a first tab to the task sheet allowing you to select the products that will be used during the task. | ||

|} | |} | ||

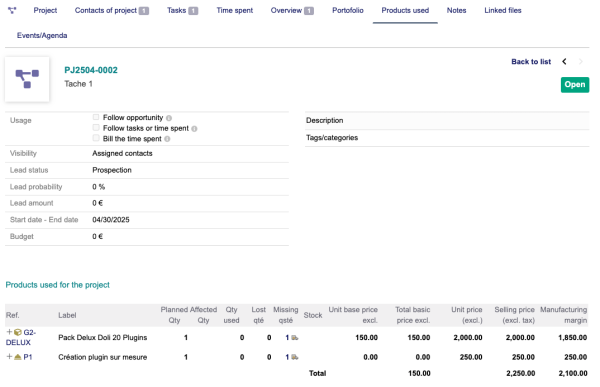

A custom product is a set of products and services associated with each other. Unlike a mass-produced product, a custom product is not manufactured according to a predefined composition and is not referenced in the Dolibarr product list. | |||

The selection of products associated with a stain follows the same procedure as that for defining the composition. | |||

{| class="wikitable" | {| class="wikitable" | ||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Onglet-factory-projet_en.png|600px]] | ||

| | | | ||

The "Products Used" tab of the product sheet summarizes the products used for each of its tasks. | |||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Transfert-stock-tache_en.png|600px]] | ||

| | | | ||

{{Note| | {{Note|Clicking on the + displays the task on which the product is used.}} | ||

To make a stock movement, click on the missing quantity of product. | |||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Transfert-stock-tache-enregistré_en.png|650px]] | ||

| | | | ||

It will then be indicated that | |||

|} | |} | ||

Finally, the single product / project mode also offers the possibility of associating the products selected in a task with a product using the '''use the composition in a product''' button. | |||

When the project is closed, it is possible to use the composition transfer function on an existing product. | |||

Task compositions of a closed project can be transferred to another task with the '''Transfer to another task''' button. | |||

This feature allows you to perform composition tests for a product or keep updated compositions on the product according to seasonality. | |||

When a project is validated, it is possible to enter the product consumption for the task with the '''Adjust quantities''' button. | |||

These quantities are of two types: | |||

*Quantities actually consumed for production | |||

* | *Lost quantities that were assigned to the task but were not used for production (loss, breakage, etc.) | ||

* | : The sum of these quantities should theoretically correspond to the quantities assigned to the task and may change as the task progresses. | ||

: | : The quantities displayed in this table represent the following values: | ||

: | : *Planned Quantity: The quantities initially entered in the task | ||

:* | : *Assigned Quantity: The quantities assigned to this project from a warehouse | ||

:* | : *Used Quantity: The quantities consumed during the task's progress | ||

:* | : *Lost Quantity: The quantities assigned to the task but not used (loss, breakage, etc.) | ||

:* | : *Missing Quantity: The quantities remaining to be ordered to complete the project. | ||

:* | |||

The calculation of the missing quantity is carried out as follows: | |||

If ''Expected Qty > (Used Qty + Lost Qty)'' | |||

So ''Missing Qty = Expected Qty – Assigned Qty'' | |||

Otherwise ''Missing Qty = (Used Qty + Lost Qty) – Affected Qty'' | |||

==Other Factory Features== | |||

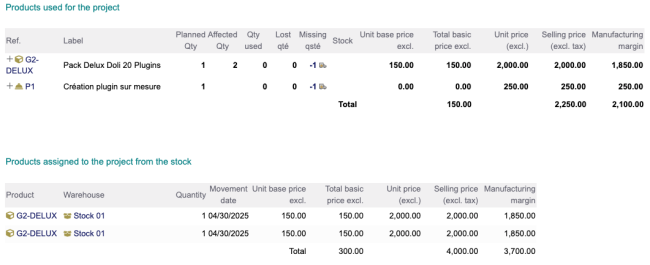

===Composition Import=== | |||

===Import | |||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory- | | [[file:factory-Import_en.png|650px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

Factory | Factory allows you to import compositions using Dolibarr's native tool. In step 2 of an import, you will be prompted to download the sample import file in csv format. | ||

|} | |} | ||

===Composition Export=== | |||

===Export | |||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory- | | [[file:factory-Export_en.png|650px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

Factory | Factory also allows the export of compositions and manufacturing orders using Dolibarr's native tool. | ||

|} | |} | ||

===Show/hide component product pricing data=== | |||

=== | The user permission "View production order pricing" allows you to hide pricing information from certain users. | ||

===Homepage Widgets=== | |||

===Widgets | |||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory- | | [[file:factory-Widget_en.png|650px]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

The Dolibarr homepage will display a widget of the latest manufacturing orders. | |||

|} | |} | ||

===Production Order Search=== | |||

{| class="wikitable" | {| class="wikitable" | ||

| [[file:factory- | | [[file:factory-Recherche_en.png]] | ||

| style="vertical-align:top;" | | | style="vertical-align:top;" | | ||

Production orders can be quickly found using the sidebar search bar. | |||

|} | |} | ||

==Additional Features of Factory== | |||

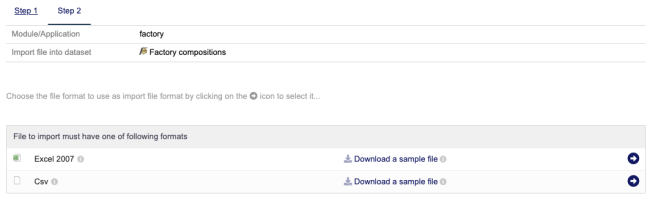

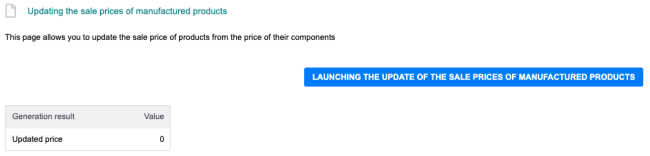

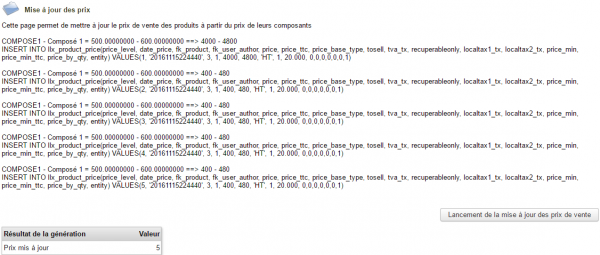

===Mass Price Changes for Manufactured Products=== | |||

=== | Factory allows you to save calculation formulas that will be applied to the prices of composite products based on the prices of component products. | ||

Factory | |||

This feature requires the use of categories in which compound products must be classified in order to be taken into account by the formulas. | |||

{| class="wikitable" | {| class="wikitable" | ||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Changprice-formule_en.png|650px]] | ||

{{Note| | {{Note|As many calculation formulas are available as there are price levels configured for products/services.}} | ||

{{Note|ATTENTION : | {{Note|ATTENTION: Price changes only apply to MANUFACTURED PRODUCTS (not individual products or services).}} | ||

| | | | ||

In the category files, under the "Price Update" tab, save your automatic calculation formulas by selecting the values using the drop-down lists. | |||

In the example opposite, the level 1 prices of the manufactured products will be updated according to the following formula: | |||

''Sum of the selling prices of the components multiplied by 2 multiplied by 5 (number of components) or 400 x 2 x 5 = 4000 excluding VAT (4800 including VAT)'' | |||

'' | |||

Selection lists allow you to configure your mass price changes based on the selling price or the average price of the components, to which you can add, subtract, multiply, or divide, based on a multiplier number entered among the number of services or the number of products. | |||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Bouton-changprice_en.png|650px]] | ||

| | | | ||

Once the formulas have been saved by category, from the menu link "Products/Services > Factory > Update Prices", launch the price update using the dedicated button. | |||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Changeprice-resultat.png|600px]] | ||

| | | | ||

The page will then display the number of prices that have been modified and a view of the changes made. | |||

|} | |} | ||

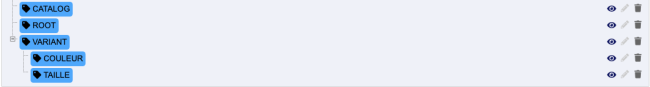

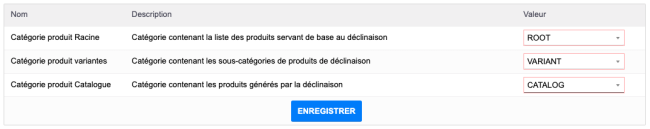

===Declinations=== | |||

The purpose of the function is to generate as many products as there are defined variations. | |||

To achieve this, Factory uses both composition creation and product/service category management. Products must be classified into three distinct categories: | |||

*'''The root product group (ROOT)''' serving as the basis for the variation: The products associated with it are neither for sale nor for purchase, but base prices are defined for them. | |||

*''' | *'''The varying product groups (VARIANTS)''': These are, by default, neither for sale nor for purchase, but a price can be defined for them, which will be added to the base price (root category products) for the variation. | ||

*''' | *'''The catalog product group (CATALOG)''' that are for sale. | ||

*''' | |||

{| class="wikitable" | {| class="wikitable" | ||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Categories.png|650px]]] | ||

| | | | ||

First, create the product categories. | |||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Rappel-configuration.png|650px]] | ||

| | | | ||

Open the Factory plugin settings and declare them in the "Configuration" tab. | |||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Categories-declinaisons.png|650px]] | ||

| | | | ||

Then create the products and their variants and classify them into the corresponding categories. | |||

"The Portfolio module allows for quick categorizing of products, among many other features." | |||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Declinaison-composition.png|650px]] | ||

| | | | ||

Let's then save the product's composition. | |||

|} | |} | ||

From the secondary menu link '''Products/Services > Factory > Combinations''', click the '''Start Generation of Product Combinations''' button. | |||

{| class="wikitable" | {| class="wikitable" | ||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Declinaison-resultat_en.png]] | ||

| | | | ||

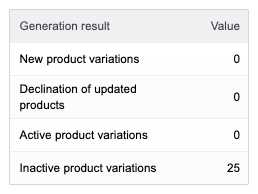

The summary table displays the number of combinations that have been created in the New Product Combinations row. | |||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

| | | [[file:factory-Declinaison-liste_en.png|600px]] | ||

| | | | ||

In the list of your products, you will find the combinations created. | |||

|} | |} | ||

==Frequently Asked Questions== | |||

==Questions | ===General=== | ||

=== | This chapter lists the difficulties encountered with the module. You'll find answers to questions about its use. | ||

If you encounter an error other than those described below when using this module: | |||

#Disable and re-enable the module, | |||

# | #Check the ChangeLog to see if a new version has been released, | ||

# | #Reinstall/update the module, | ||

# | #Check that replacing native Dolibarr files is not necessary for the module to function properly. | ||

# | #Check that no incompatibilities with another module are indicated. If applicable, follow our recommendations. | ||

# | |||

If, despite these manipulations, the error persists, contact us using the dedicated form (http://docs.patas-monkey.com/support/). | |||

'''This form is the preferred method of contact for any usage difficulties or bug reports. We therefore ask that you do not use multiple communication channels for the same item.''' | |||

''' | |||

===Error Message Following Installation=== | |||

===Message | : If the production order and document numbering templates are not enabled in the module configuration, the following error message will be displayed: | ||

: | [[file:]] | ||

: Enable the numbering and document templates, and everything will return to normal. | |||

: | ===Work Order References Not Incrementing=== | ||

=== | : Following a Factory update from version 1.4.4 and earlier to version 1.5.0 and later, you may encounter errors in work order numbering. To correct these errors, run the following query on your database: | ||

: | UPDATE llx_factory SET ref = concat( SUBSTRING(ref,1,7),'0', SUBSTRING(ref,8)) WHERE length(ref)=11 | ||

This operation will add the missing 0 to the old work order references. If any work orders have incorrect numbering, you will need to modify it manually. | |||

Dernière version du 15 octobre 2025 à 14:40

|

CAPM Tool - Composition, Direct Manufacturing, Manufacturing Orders, and Variations |

Overview

Features

Factory is Dolibarr's CAPM tool that allows you to:

|

|

Factory creates the stock movements for different products:

A dedicated tab allows for display: |

Factory also provides the functionality of creating product variations: from the product categories defined in the module configuration, Factory creates product variations according to their variants.

Combined with the Project module, Factory allows the recording of compositions on tasks and allows the monitoring of consumption and their transfer to other tasks.

NEW: The Factory module allows you to view the component tree (and their subcomponents) and all the components that make up the component. It is possible to associate a Production Order with a project (and track associated production orders from within a project).

Factory Free and Factory Premium

Factory was distributed in a free & limited version and a premium version.

Since the arrival of a native GPAO function (MRP) in Dolibarr, the free version is no longer maintained

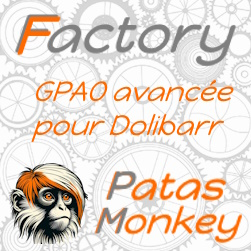

Settings

Configuration

Module Feature Configuration

|

Module configuration is performed from the module administration page, accessible via the "Home > Configuration > Modules" menu by clicking on the |

The Factory module allows you to customize the numbering mask for production orders.

| Factory requires the activation of the numbering and document templates |

Use of the product declination feature requires declaration on this page of the product categories used.

Factory has a price update tool that can be activated on this same page.

Factory per and to choose the value to use for the price of the components depending on whether they are products or services.

Finally, by enabling the "Select the additional field from which to copy information as a work order description" feature, it is possible to copy the contents of an additional field present on the composite product sheets as a work order description. Select the additional field containing the data here.

Creating Additional Fields

The module supports the creation of additional fields. These fields will allow you to display custom fields on the module's element sheets, where you can record any additional information you may need.

Creating additional module-specific fields follows the same procedure as creating additional fields on native Dolibarr elements. You can create additional fields for:

- Composition lines

- Production orders

- Production order detail lines

| If the additional fields for the composition lines and the production order detail have the same name (and the same type), their values are passed on when the production order is created. |

Dictionary

The module relies on Dolibarr dictionaries to assign contacts/addresses to a production order.

Factory offers four types of contacts/addresses by default: Production manager and contributor, internal and external for each.

You can create your own entries from Home > Settings > Dictionaries > Contact/Address Types

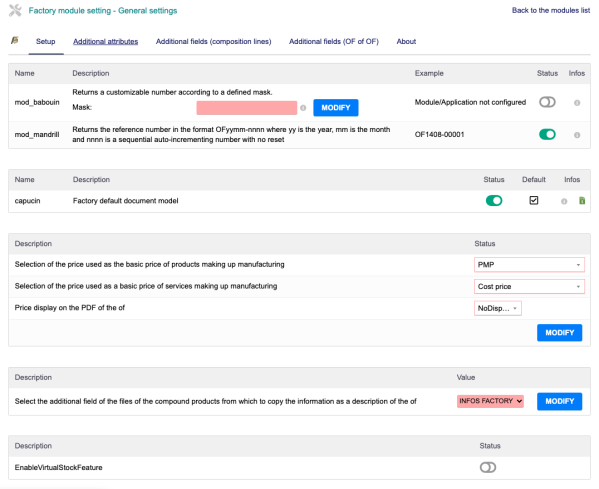

Permissions

Access to module features can be restricted to existing users and groups or those created after the module's installation. Click the – button to add a permission. A granted permission is indicated by a green check mark (![]() ).

).

User and Group Permissions

|

Access to module features can be restricted to users and groups, from their profile and then the Permissions tab, according to the permissions opposite. |

Default Permissions

|

The default permissions (Home > Settings > Security > Default Permissions), granted to any user created after the module is installed, if they are not added to a group, are as follows: |

Getting Started

Factory features are accessible from the main menu tab "Products/Services" or the "MRP/CAPM" menu (depending on the Dolibarr version and the enabled modules).

| Your secondary menu then displays the following menu items: | |

|---|---|

|

Factory: Displays the factory "space" with dashboards showing module usage. | |

| New Work Order: Allows you to directly create a Production Order (PO) by selecting either a product with a defined composition or a BOM. | |

| List: This entry will display the list of production orders entered in your database. The list offers numerous sorting and filtering options. | |

| Consumption Report: This menu allows you to view monthly and annual consumption. You can view the times the planned and actual consumption. | |

| Time Report: The module allows you to enter times associated with employees for services used in a work order. It is possible to plan times, as well as those actually used. This entry is made on a work order tab that will be presented in the documentation (Associated functionality / provided by the TimeKeeper module). | |

| Declination: The Declination entry will display the page for launching the generation of declinations. The operation of this page requires the correct configuration of all necessary elements. | |

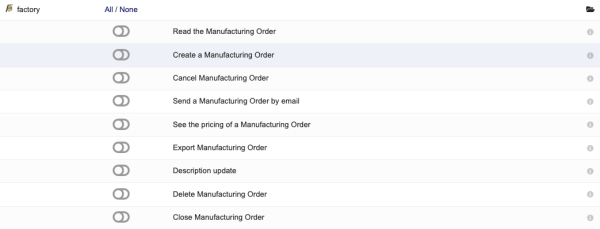

Definition of a Product's Composition

Prerequisites

For a composite product to have a composition, it must be of a "manufactured" nature.

The composition is carried out by the selection of predefined products and/or services.

|

The manufacturing features, whether direct or by production order, are accessible from the "Factory" tab of the product page and then from the second-level tabs. |

Composition Determination

Click the "Composition" tab and then the "Composition Definition" button to select the component products.

| The quantity used of a product defined as global to a composition will remain unchanged regardless of the quantity of the composite product manufactured (ex: manufacturing one or five composite products requires a single unit of labor each time.) |

|

When selecting components for a composition, you can order them by entering a position and add a note. These two options are accessible by clicking the + in front of the component label:

|

Product Variant Composition

When using product variants, it is possible to retrieve the parent product's composition directly from the variant sheet.

Composition and Decomposition

Factory also allows you to decompose products by entering a quantity in decimal format as follows: Let's take a box of 10 items to be decomposed into 10 individual items.

!!! Please note that the operating mode has changed; you must now enter a negative value to break down a product.

| Two products will need to be created |

|

| and the element composition saved as shown opposite |

|

Manufacturing Levels

Factory can manage multiple manufacturing levels, including component products themselves produced through manufacturing.

|

In a composition, if you select a product that is itself composed, the information will be given by the number in parentheses indicating the number of components in this product, which is (3) for FAB_1. |

Deleting Components

To delete a component from a composition, return to the product composition, click the Composition Definition button, uncheck the boxes of the components to be deleted, and then save your changes.

| If you modify the composition of a product, it will be applied to all subsequent production runs of the same composite product |

| A composition can be modified on a production order. The modification only affects the production order and does not modify the composition saved on the composite product |

Composition Options

- Retrieve Prices (Sale and Purchase): This button allows you to retrieve the sale and purchase prices of component and composite products from the composition.

| The retrieved sale price will be the first price in your grid if you use the multi-price management feature, while the retrieved purchase price will be the PMP (calculated from supplier orders) or the cost price/CostPrice if you have enabled the feature to use this value in the Factory settings. |

- Adjust Prices: Adjusting the sale prices will allow you to modify the sale and purchase prices of the products in the composition.

|

|

Direct Manufacturing

|

Once a product's composition has been saved, click on the second-level Direct Manufacturing tab in the Factory tab of the product sheet to be manufactured. Factory automatically calculates the quantity of product that can be manufactured based on the quantities of component products present in the warehouses. Modify the quantities to be manufactured if necessary and click on the Start manufacturing button. A confirmation message is displayed. The page then displays the updated quantities of products in stock. | ||

|

Warehouse stock movements display movements related to manufacturing. |

Production Orders (PO)

Production orders allow you to plan your production. You can create a production order from product sheets or from customer order sheets.

Creating and Launching from Product Sheets

|

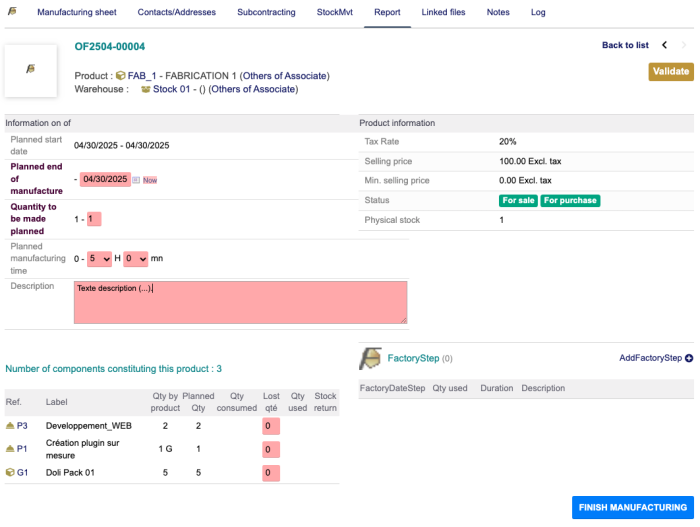

Once a product's composition has been saved, click on the second-level Manufacturing Order tab in the Factory tab of the product sheet to be manufactured. | ||

|

Select the manufacturing warehouse and the quantity of products to be manufactured, the planned manufacturing start and end dates and, if necessary, a manufacturing duration and description.

Check the quantities of products required for manufacturing: Factory requires a control step with the button Check the quantities required for manufacturing in the warehouse before continuing with the creation of the work order. The screen will show you the missing quantities in the warehouse selected when creating the work order. For future illustrations, the warehouses will be restocked with the missing products. |

Finally, click the "Create Manufacturing Order" button. The page will then display the list of production orders for the product to be manufactured.

|

Open the production order file from the previous page or from the "Products/Services > Factory > List" menu link:

|

Creating and Launching from Customer Order Records

|

Creating a work order from a customer order record follows the same creation procedure. The following steps are common, regardless of the source from which the work order was created. The page for creating a production order from a customer order is accessible from the Factory tab of its record. |

|

|

Working Order Form Buttons

At this stage, you can:

- Cancel the work order: Deleting a work order is not possible. You can only cancel it using the "Cancel Production" button.

- Modify the work order composition: You can modify the product composition on the work order. Clicking this button will display the "Determine Composition" page.

| Modifying the composition on the work order only applies to the work order and does not change the composition recorded on the Factory tab of the product sheet. |

- Sending the work order by email requires activating the email sending option and selecting a contact on the "Contact" tab of the work order (see Dictionary). *Clone the work order: cloning allows you to copy the work order by using or modifying the quantity, product and initial warehouse.

Validating and Reporting a Production Order

To validate the production order, enter its actual production date by clicking the ![]() icon.

icon.

|

The production order will then change to the "Validated" status. All that's left to do is enter its report. Open the Report tab of the OF file. Confirm the quantity actually manufactured. Close the work order with the Complete production button.

|

Editing the PDF of Production Orders

|

|

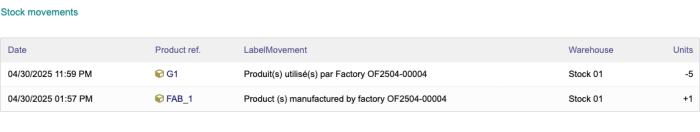

Stock Movements

|

Once manufacturing is complete, stock movements are recorded. In the previous case, they are as follows: |

| Stock movements related to the production order are accessible from the Stock Movements tab of its file and from the complete list of movements for a warehouse or product. They mention the origin (direct manufacturing or production order followed by its reference). |

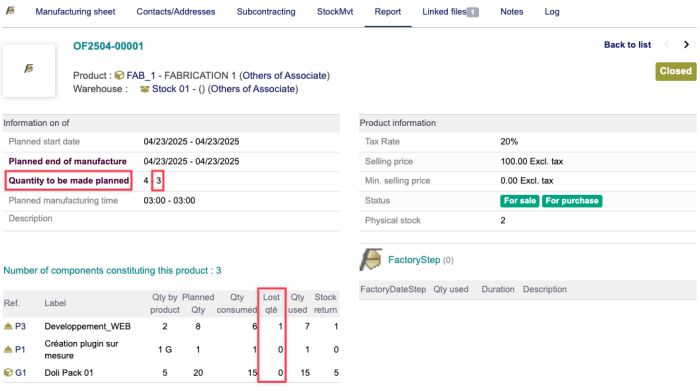

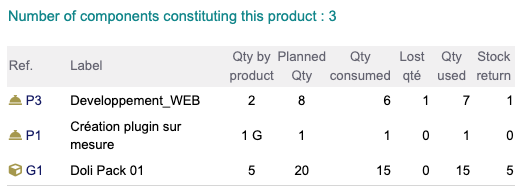

Loss Management

|

Component losses are recorded in the manufacturing report. Lost components will be deducted from inventory. Others can be returned to inventory. |

|

In the following case, the plan was to manufacture four composite products. We will record the manufacture of three products and the loss of one component, P3. Factory automatically calculates the quantities of products lost or returned to stock based on the quantities actually manufactured and the products declared lost. |

|

Stock movements related to the work order will then be: |

| In the case of products and not services (products return to stock and services will not be counted). |

Consumption Report

Factory allows you to track monthly and annual product consumption.

Subcontracting Management

Operating Principle

It is possible to subcontract a production order to a subcontractor and track it from the work order.

|

Start by selecting the subcontractor from the dedicated tab at the work order level. and creating an associated supplier order. |

Factory and Projects

Operating Principle

Factory allows you to manage the creation of unique parts or the consumption of products for projects. This management is done by associating products with project tasks.

When the project is active/valid, it is possible to enter the products consumed on the tasks.

|

Factory adds a first tab to the task sheet allowing you to select the products that will be used during the task. |

A custom product is a set of products and services associated with each other. Unlike a mass-produced product, a custom product is not manufactured according to a predefined composition and is not referenced in the Dolibarr product list.

The selection of products associated with a stain follows the same procedure as that for defining the composition.

|

The "Products Used" tab of the product sheet summarizes the products used for each of its tasks. | ||

|

To make a stock movement, click on the missing quantity of product. | ||

|

It will then be indicated that |

Finally, the single product / project mode also offers the possibility of associating the products selected in a task with a product using the use the composition in a product button.

When the project is closed, it is possible to use the composition transfer function on an existing product.

Task compositions of a closed project can be transferred to another task with the Transfer to another task button.

This feature allows you to perform composition tests for a product or keep updated compositions on the product according to seasonality.

When a project is validated, it is possible to enter the product consumption for the task with the Adjust quantities button.

These quantities are of two types:

- Quantities actually consumed for production

- Lost quantities that were assigned to the task but were not used for production (loss, breakage, etc.)

- The sum of these quantities should theoretically correspond to the quantities assigned to the task and may change as the task progresses.

- The quantities displayed in this table represent the following values:

- *Planned Quantity: The quantities initially entered in the task

- *Assigned Quantity: The quantities assigned to this project from a warehouse

- *Used Quantity: The quantities consumed during the task's progress

- *Lost Quantity: The quantities assigned to the task but not used (loss, breakage, etc.)

- *Missing Quantity: The quantities remaining to be ordered to complete the project.

The calculation of the missing quantity is carried out as follows:

If Expected Qty > (Used Qty + Lost Qty)

So Missing Qty = Expected Qty – Assigned Qty

Otherwise Missing Qty = (Used Qty + Lost Qty) – Affected Qty

Other Factory Features

Composition Import

|

Factory allows you to import compositions using Dolibarr's native tool. In step 2 of an import, you will be prompted to download the sample import file in csv format. |

Composition Export

|

Factory also allows the export of compositions and manufacturing orders using Dolibarr's native tool. |

Show/hide component product pricing data

The user permission "View production order pricing" allows you to hide pricing information from certain users.

Homepage Widgets

|

The Dolibarr homepage will display a widget of the latest manufacturing orders. |

Production Order Search

|

Production orders can be quickly found using the sidebar search bar. |

Additional Features of Factory

Mass Price Changes for Manufactured Products

Factory allows you to save calculation formulas that will be applied to the prices of composite products based on the prices of component products.

This feature requires the use of categories in which compound products must be classified in order to be taken into account by the formulas.

|

In the category files, under the "Price Update" tab, save your automatic calculation formulas by selecting the values using the drop-down lists. In the example opposite, the level 1 prices of the manufactured products will be updated according to the following formula: Sum of the selling prices of the components multiplied by 2 multiplied by 5 (number of components) or 400 x 2 x 5 = 4000 excluding VAT (4800 including VAT) Selection lists allow you to configure your mass price changes based on the selling price or the average price of the components, to which you can add, subtract, multiply, or divide, based on a multiplier number entered among the number of services or the number of products. | ||||

|

Once the formulas have been saved by category, from the menu link "Products/Services > Factory > Update Prices", launch the price update using the dedicated button. | ||||

|

The page will then display the number of prices that have been modified and a view of the changes made. |

Declinations

The purpose of the function is to generate as many products as there are defined variations.

To achieve this, Factory uses both composition creation and product/service category management. Products must be classified into three distinct categories:

- The root product group (ROOT) serving as the basis for the variation: The products associated with it are neither for sale nor for purchase, but base prices are defined for them.

- The varying product groups (VARIANTS): These are, by default, neither for sale nor for purchase, but a price can be defined for them, which will be added to the base price (root category products) for the variation.

- The catalog product group (CATALOG) that are for sale.

] ]

|

First, create the product categories. |

|

Open the Factory plugin settings and declare them in the "Configuration" tab. |

|

Then create the products and their variants and classify them into the corresponding categories. "The Portfolio module allows for quick categorizing of products, among many other features." |

|

Let's then save the product's composition. |

From the secondary menu link Products/Services > Factory > Combinations, click the Start Generation of Product Combinations button.

|

The summary table displays the number of combinations that have been created in the New Product Combinations row. |

|

In the list of your products, you will find the combinations created. |

Frequently Asked Questions

General

This chapter lists the difficulties encountered with the module. You'll find answers to questions about its use.

If you encounter an error other than those described below when using this module:

- Disable and re-enable the module,

- Check the ChangeLog to see if a new version has been released,

- Reinstall/update the module,

- Check that replacing native Dolibarr files is not necessary for the module to function properly.

- Check that no incompatibilities with another module are indicated. If applicable, follow our recommendations.

If, despite these manipulations, the error persists, contact us using the dedicated form (http://docs.patas-monkey.com/support/).

This form is the preferred method of contact for any usage difficulties or bug reports. We therefore ask that you do not use multiple communication channels for the same item.

Error Message Following Installation

- If the production order and document numbering templates are not enabled in the module configuration, the following error message will be displayed:

[[file:]]

- Enable the numbering and document templates, and everything will return to normal.

Work Order References Not Incrementing

- Following a Factory update from version 1.4.4 and earlier to version 1.5.0 and later, you may encounter errors in work order numbering. To correct these errors, run the following query on your database:

UPDATE llx_factory SET ref = concat( SUBSTRING(ref,1,7),'0', SUBSTRING(ref,8)) WHERE length(ref)=11 This operation will add the missing 0 to the old work order references. If any work orders have incorrect numbering, you will need to modify it manually.